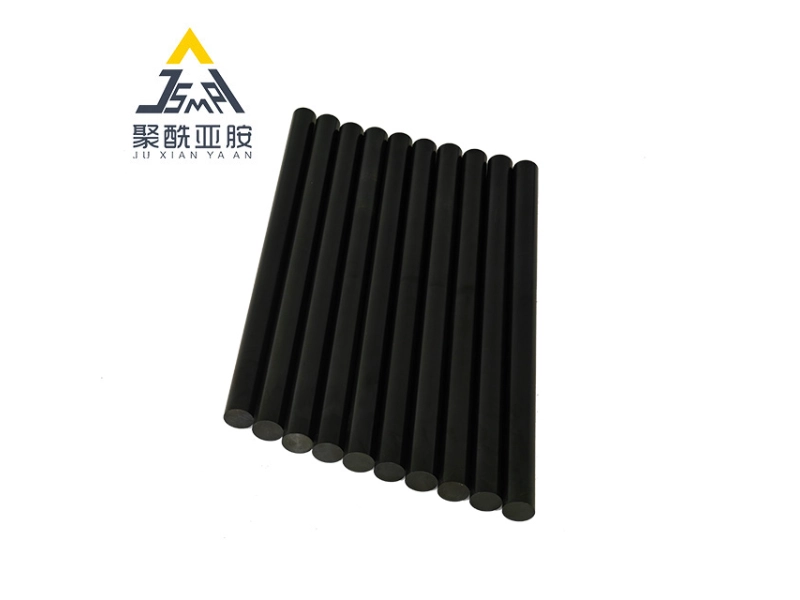

Amidst the constantly changing landscape of high-tech technologies, conductive materials play a crucial role in improving functionality and efficiency. Of these materials, conducting polyimide resin rods have emerged a key component, offering a distinct combination of structural resilience, thermal stability, and electrical conductivity. Such attributes make them highly sought after in multiple applications, particularly in sectors that demand high-performance materials, such as aerospace.

The aerospace industry, recognized for its strict standards and harsh environments, has found a significant ally in conductive polyimide rods. Such rods not only meet the strict requirements for mass and durability but also provide necessary conductive pathways for power systems. As the demand for ultra-light and effective solutions continues to expand, conductive polyimide resin rods are paving the way for innovation and high standards in high-tech technologies.

Overview of Conductive Polyimide Resin Material

Conductive polyimide material is a superior material that has garnered significant attention in advanced technology applications. Known for its remarkable thermal stability, chemical resistance, and mechanical strength, this resin is widely used in sectors that require materials to withstand extreme conditions. The incorporation of electrically conductive fillers enhances its electrical conductivity, making it suitable for a variety of electronic and aerospace applications.

In the aerospace industry, polyimide rods are particularly crucial due to their ability to sustain high temperatures and harsh environments. These rods provide dependable electrical and thermal insulation while maintaining structural integrity, making them vital components in aircraft and spacecraft designs. Their lightweight nature contributes to fuel efficiency and overall performance, which is essential in aerospace development.

Additionally, the flexibility of conductive polyimide resin allows it to be tailored for specific applications. With varying levels of conductivity and adaptability to different manufacturing processes, these rods can be manufactured for use in adaptive electronics, sensors, and other innovative solutions. As the demand for innovative materials continues to grow, conductive polyimide resin rods are poised to play a key role in the evolution of top-tier technologies.

Main Attributes and Advantages

Electrically conductive polyimide resin rods are noted for their remarkable thermal stability, which allows them to resist high temperatures without sacrificing their integrity. This property makes them ideal for purposes in the aerospace industry, where materials must operate reliably in high-temperature environments. The ability to preserve mechanical strength at elevated temperatures ensures that these rods can be used in essential components such as insulation, cables, and structural parts that are essential for flight safety.

An additional significant advantage of conductive polyimide rods is their superior electrical conductivity. hsjuxin-pi facilitates their use in advanced electronic applications, particularly in aerospace and defense systems where reliability and dependability are crucial. The rods enable efficient electrical interconnections while reducing the risk of signal interference. This makes them particularly valuable in the development of slim devices required for next-generation technologies.

Additionally, conductive polyimide resin rods exhibit excellent chemical resistance, making them suitable for environments where interaction with harsh chemicals and fuels is common. This characteristic is essential for aerospace applications where components are regularly assailed to aggressive substances. Moreover, the rods possess built-in mechanical strength and flexibility, allowing for diverse applications across various advanced technological fields, from precision instruments to advanced composites.

Applications in Aerospace Industry

Conductive polyimide resin rods are increasingly being used in the aerospace industry due to their exceptional mechanical properties and thermal stability. The lightweight nature of these rods, combined with their high-performance characteristics, makes them perfect for uses in aircraft structures, insulation components, and various electronic devices found in aerospace technology. Engineers are turning to polyimide rods for their ability to endure extreme temperatures and harsh environmental conditions, which are typical in aviation.

In particular, conductive polyimide rods play a key role in the development of advanced avionics systems. These systems require materials that can not only provide structural support but also ensure conductivity for the electronic components. The use of polyimide rods secures reliable performance of wiring and electronic housings, leading to improved functionality and safety in aircraft. Their resistance to corrosion and neutrality against different chemicals further positions them as a favorite material within aerospace applications.

Furthermore, the future of sustainable aviation technology is likely to benefit from the incorporation of conductive polyimide resin rods. As the aerospace industry advances towards more environmentally friendly practices, the lightweight nature of these materials contributes to fuel efficiency and reduced emissions. Their versatility allows for compatibility with other advanced materials, creating innovative designs that satisfy the evolving demands of the aerospace sector.

Emerging Trends in Cutting-edge Tech

The evolution of electrically-conductive polyimide resin rods is intimately tied to advancements in the aerospace industry. As the need for lightweight and versatile substances increases, these rods are transforming into essential in the creation of sophisticated aircraft and spacecraft components. Upcoming research will center on improving the electric conducting ability and heat resistance of polyimide materials, allowing them to be incorporated into increasingly intricate systems, such as detecting devices and smart structural components. This will eventually lead to improved efficiency and operational efficiency in aerospace applications.

In addition to aerospace, the electronic industry is witnessing a surge in the application of high-quality polyimide rods. With the rapid advancement of flexible electronics and wearables, the need for materials that can endure extreme situations while maintaining excellent electrical characteristics is crucial. Researchers are exploring the potential of blended polyimide formulations that can merge the advantages of various polymers, thus broadening the scope of applications for conductive polyimide rods in high-tech devices.

Looking ahead, the sustainability aspect of material development will play a critical role in the future of conductive polyimide resin rods. The drive for sustainable materials is encouraging scientists to explore biodegradable polyimides and upcycling methods for existing materials. This movement toward sustainability not only aligns with global environmental goals but also presents new opportunities for advancement in material science, ensuring that conductive polyimide rods remain at the forefront of advanced technologies.